Product Area

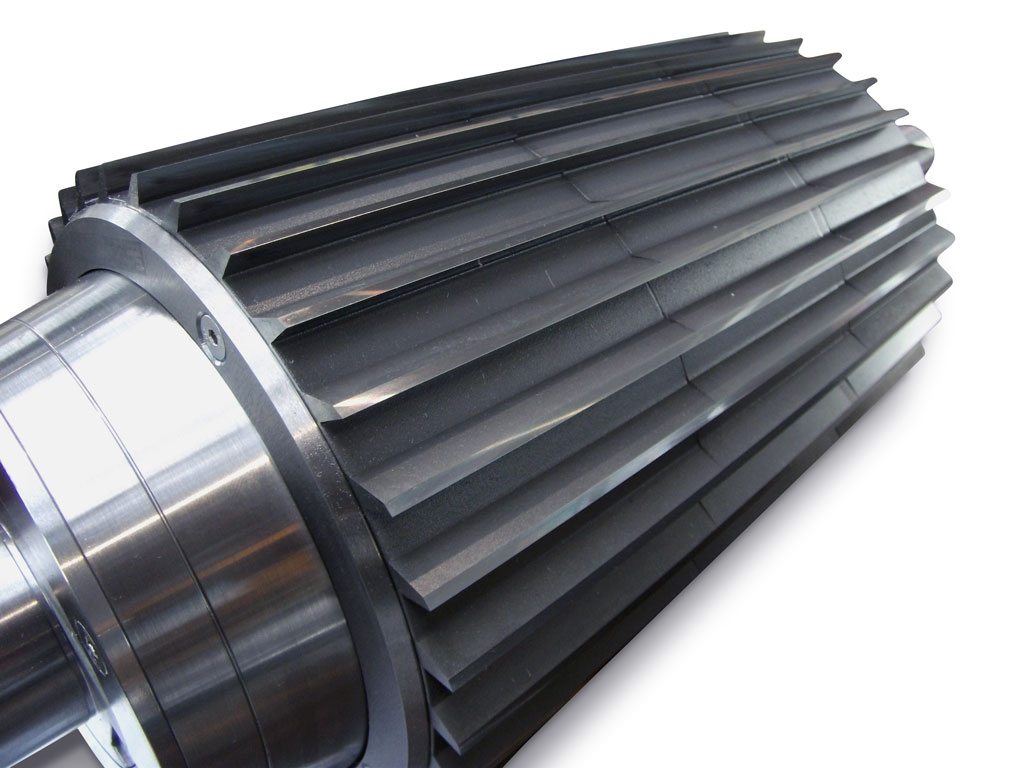

Cutting rotor

The cutting rotor performs an essential task in plastic pellet production. With the selection of the suitable material and the tooth profile, the cutting rotor is directly responsible for the quality of the pellets

Product Description

A strand pelletizer is required for the production of cylinder pellets. The cooled polymer strands are transferred to the pelletiser. The feed rollers pull in the strands and feed them to the cutting rotor. Here the strands are cut into cylindrical pellets. This process is often used for very high throughputs, for the production of virgin polymer or other reasons.

Schönenberger with its competence in this field offers a wide range of cutting rotors for all major pelletizers. The material of the cutting rotor depends on the polymer to be processed.

The cutting balde and the feed rollers are also important elements for the production of high quality pellets.

Products

cutting rotor tool steel

The tool steel rotors have very different areas of application in the pellet production. However, especially in the production of virgin polymerl, the WS1 steel rotors are the "workhorses" with very "high throughputs and long service lives".

cutting rotor powder metal steel

The composition of the PM steel and the associated hardness in combination with the toughness make this cutting rotor universally applicable for a wide range of filled and unfilled polymers

cutting rotor tungsten carbide

The tungsten carbide cutting rotors are the "high-performance athletes" among the rotors. Their robust design is ideal for filled and highly filled polymers. As an OEM supplier, machine manufacturers trust us as well as processors directly.

cutting rotor stellite

This extremely corrosion-resistant stellite steel is particularly suitable for the production of virgin polymers such as PET or PA