Product

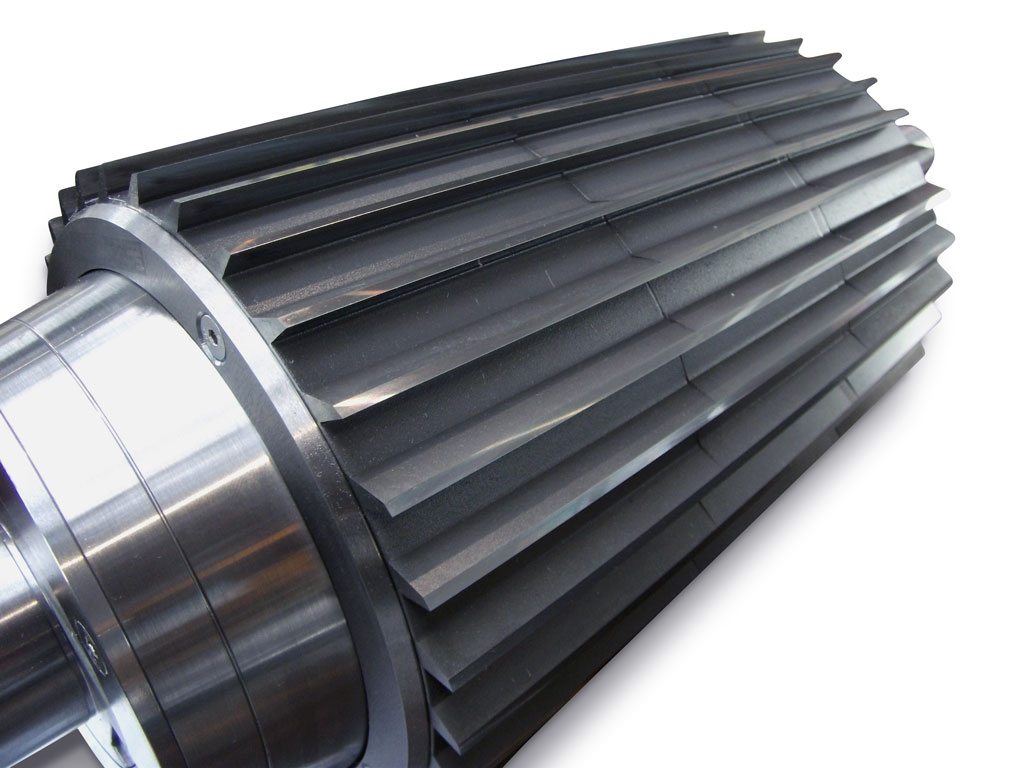

cutting rotor tungsten carbide

Schönenberger started early with the production of brazed carbide cutting rotors. Here a hard metal plate is brazed into a steel body (cutting rotor body). Schönenberger was able to take over this know-how from his paper knives / long knives.

The brazed carbide cutting rotors are ideally suited for filled polymers. The rule of thumb is up to 30% glass content in the polymer.

Above this, the carbide-clamped cutting rotor is used. The basic rotor body is made of corrosion-resistant steel. The high-quality, robust carbide knives are positively fixed in the rotor body without additional material. This very resistant cutting rotor is suitable for compounding with fillers of more than 30% GF.

We call it KRONOS